Al Madar can supply pumps of various types and standards to suit the oil, power, and process industries. We have a supply agreement in place with Dalian Deep Blue Pump, recognized as the top industrial centrifugal pump manufacturer in China. Deep Blue Pump looks after the complete production process from R&D and engineering, melting and casting, to machining and fabrication, assembly, testing, and inspection.

Choose a Pump Type

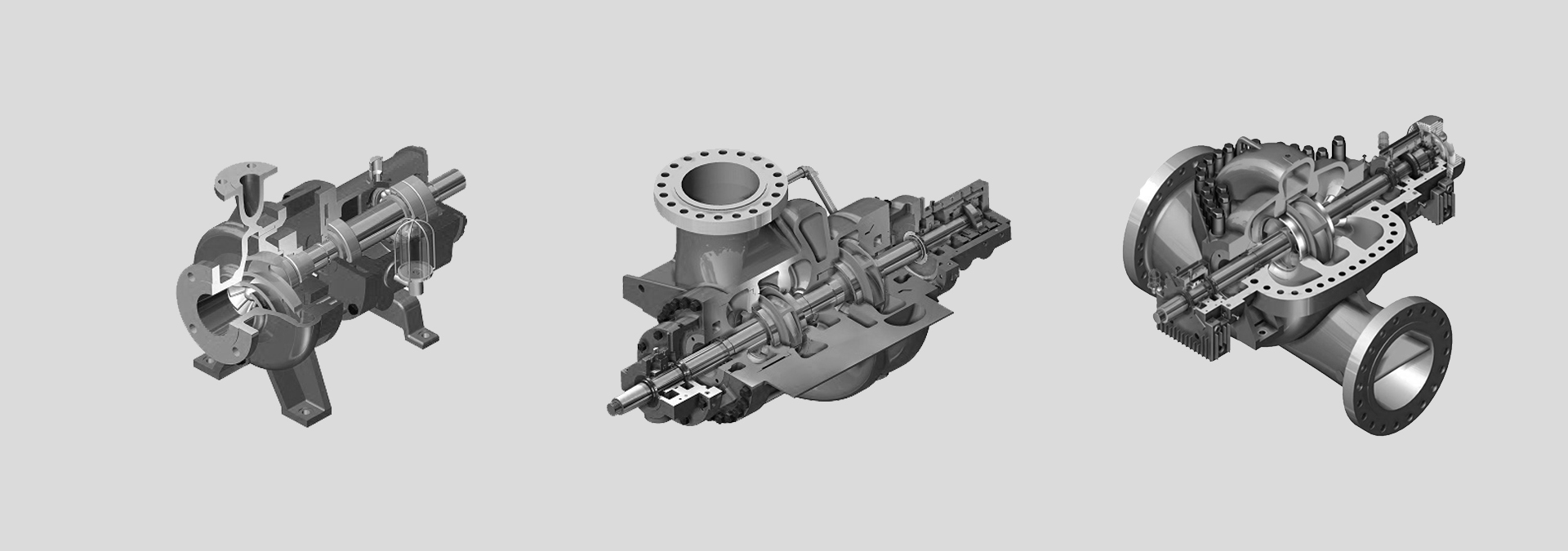

EAP-I series is a horizontal, radial split, single stage, single suction overhung centrifugal pump with volute casing. A double volute casing structure with an outlet diameter ≧ 80mm can well balance the radial force and ensure the shaft deflection at the shaft seal. The pump is centerline-mounted, which is suitable for high-temperature mediums. A balance hole and seal ring combination are applied to balance the axial force over the service life of the bearing. The pump casing, cover, and impeller are provided with sealing rings. The interference fit of the sealing rings is fixed with screws. Available for working conditions with granular impurities without compromising the service life of pump casing, cover, and impeller.

- Capacity 2~2600m3/h

- Head ~300m

- Design Pressure ~5.0MPa

- Temperature -80~+450℃

- Speed 2980r/min 1475r/min

- Power ~1120KW

EAP-K series is a horizontal, radial split, single-stage, overhung centrifugal pump with volute casing. The pump is a centreline-mounted, double-casing structure with an outlet diameter ≧ 80mm and; Open impeller. The pump casing and cover are provided with front and rear wear-resistant plates. The bearing component is supplied with a bearing box structure to adjust the axial momentum of the rotor. A rigid shaft design ensures the rotor could be running smoothly. The back blade balances the axial force to ensure the service life of the bearing. The radial bearings are cylindrical roller bearings, and the thrust bearings are angular contact ball bearings and can properly bear axial forces from two directions.

- Capacity 2~2600m3/h

- Head ~280m

- Design Pressure ~5.0MPa

- Temperature -80~+450℃

- Speed 2980r/min 1475r/min

- Power ~1120KW

EAP-G series is a horizontal, radial split, single stage, single suction overhung centrifugal pump with volute casing. A double casing structure with an outlet diameter ≧ 80mm can well balance the radial force and ensure the shaft deflection at the shaft seal. The pump is centerline-mounted, which is suitable for any temperature medium. Inlet and outlet flange are arranged on the pump casing to quickly inspect and maintain the pump without moving the suction and discharge pipelines. With a no-balanced hole structure, the shaft head force generated by the high pressure at the pump inlet can be offset with the impeller cover force, and the tapered roller bearing bears the residual axial force. Throat bushing is designed with a labyrinth groove or effect thread groove structure that can effectively cut off high-temperature heat sources and control the pressure of the sealing chamber.r.

- Capacity 2~1500m3/h

- Head ~280m

- Design Pressure ~10.0MPa

- Temperature -80~+450℃

- Speed 2980r/min 1475r/min

- Power ~1120KW

ANS-B series is a horizontal, radial split, single stage, single suction, overhung centrifugal pump with the volute casing, foot mounted. The impeller is designed as a fully open structure with a back blade, which is suitable for abrasion liquids containing large particles or strip fibers. The rigid shaft design, impeller, and shaft are connected by thread, with no impeller nut. The bearing component is provided with a bearing box structure, the connecting bolts plus jacking-bolts design for the bearing housing and bearing box so that the clearance between the impeller and the casing can be easily adjusted without disassembling the pump to ensure the pump can be running within the high-efficiency range; the adjusting action is easy and reliable, the maintenance is simple. The radial bearings are deep groove ball bearings, and the thrust bearings are angular contact ball bearings, which can adequately bear axial forces from two directions.

- Capacity 2~2600m3/h

- Head ~300m

- Design Pressure ~5.0MPa

- Temperature -80~+450℃

- Speed 2980r/min 1475r/min

- Power ~1120KW

EDS series is horizontal, axially split, double suction, single stage or two stages, between-bearings, Centreline-mounted, or foot-mounted centrifugal pump. The double volute structure reduces the radial force effectively. The axial split structure can realize the rapid disassembly rotor and parts maintenance. Without disassembling the pipeline and the pipeline-related system, Single-stage double-suction or two-stage double-suction + single-stage structure impeller, high cavitation resistance, high efficiency, and stability. Self-balancing axial force, no complex balance disc, balance drum, and other balance mechanisms. EDS series pump is a new generation of high-efficiency energy-saving products with a three-dimension model and CFD flow field analysis, a wide range of flow and head, high efficiency, good cavitation resistance, etc.

- Capacity 100~1200m3/h

- Head ~440m

- Design Pressure Single stage:2.5~10.0Mpa

Double stage :5.0~15.0Mpa - Temperature -40~+200℃

- Speed Single stage:~2980r/min 1475r/min

980r/min 735r/min

Double stage :~2980r/min 1475r/min - Power ~3150KW

HDD series is horizontal, radial split, double suction for the first stage, single or two stages, between-bearings centrifugal pump with volute casing. Centerline-mounted, Top-Suction, Top-Discharge or Side-Suction, Side-Discharge/Side-Suction, Top-Discharge according to requirements. A spiral suction chamber can obtain better flow conditions. The uniform velocity field is received at the impeller inlet. Double-suction impeller with better cavitation performance can reduce the installation cost of the device and balance the axial force produced by itself to improve bearing life. Rigid shaft design: the first-order critical speed is more than 1.2 times the designed speed to ensure the smooth operation of the pump.

- Capacity 50~6300m3/h

- Head ~700m

- Design Pressure ~15.0MPa

- Temperature -80~+450℃

- Speed 2980r/min 1475r/min

- Power ~2800KW

SCSK series is a horizontal, single-casing, axial split, centerline-mounted, multistage pump with symmetrically arranged impellers. Inlet and outlet flange are placed on the pump casing to quickly realize the detection and maintenance of the pump without moving the suction and discharge pipelines. The impeller is set back to back symmetrically, and the residual axial force is small. The axial force is balanced by adjusting the size of the throttle bushing and other parts. The complex balance devices aren’t needed. The inner hole of each shaft sleeve is provided with a spiral groove, and the axial dimension of the shaft sleeve is short, especially good for transferring the liquid which contains particles. The static friction pair is designed in a separate structure, which is more convenient and fast to replace, and the rotor parts do not need to be disassembled and installed again after dynamic balance.

- Capacity 20~1680m3/h

- Head ~1850m

- Design Pressure ~5MPa~15MPa

- Temperature -80~+200℃

- Speed 2980r/min

- Power ~3150KW

SCS-Z series is horizontal, single-casing, radial split, ring-section, symmetrical arrangement impellers, and multistage pump. Centerline-mounted or foot-mounted.The impellers are arranged back to back, with Axial force self-balancing. Flexible design in the dry state while rigid design in the rotor’s wet state ensures stable and reliable operation. First-stage impeller and second-stage impeller are different designs; the first-stage impeller is based on high cavitation resistance.

- Capacity 5~900m3/h

- Head ~1600m

- Design Pressure ~20.0Mpa

- Temperature -80~+210℃

- Speed 2980r/min

- Power ~2500KW

DCS-K serial is a double casing horizontal split, a horizontal multistage centrifugal pump designed for extreme conditions such as high temperature, high pressure, etc. The pump is centerline-mounted, has a heavy-duty design and good thermal stability, and adequately satisfies the nozzle load requirements specified by API610. Double casing structure secures high safety and reliability; The inner casing is an integrally pull-out design, of which the pump could be easily installed and simply maintained. The impellers are arranged back to back without the traditional balance device to ensure stable and reliable operation. The first stage impeller is the low cavitation design. Self-lubricating bearings or forced lubricating bearings could be applied for different power, speed, and other service requirement..

- Capacity 10~2000m3/h

- Head ~4000m

- Design Pressure ~45.0Mpa

- Temperature -80~+450℃

- Speed 6000r/min

- Power ~25000KW

LDB series is vertical, double casing, radial split, radial diffuser, or bowl-type multistage centrifugal pump. Welding structure for Inlet and outlet section and barrel bag void defects.

First-stage impeller and second-stage impeller are different designs; the first-stage impeller is based on high cavitation resistance, while the second-stage impeller considers pump efficiency. Impellers can be designed with a diffuser to reduce insertion depth under cavitation-demanding conditions. They are balancing drum(LDB-B) or disks (LDB-A) designed to balance the axial force. The flexible shaft is multi-point supported. Distance between supporting points applies to the API610 standard ZL series bearing group, grease lubricated, and residual axial force balanced by a pair of the angular contact ball bearing.

- Capacity 15~4400m3/h

- Head ~400m

- Design Pressure ~11Mpa

- Temperature -80~+250℃

- Speed ~2980r/min、1475r/min

- Power ~1500KW

A high-pressure submersible pump is a vertical multistage, radial split diffuser structure centrifugal pump installed outside the storage tank. The pump head is installed inside the suction cylinder, which is installed as a pit type. The flow passage component and the motor is coaxial design, and submerged is the medium. Minor radius balance disk & drum combination design to balance the axial force. 3-point rolling bearing support with additional support provided between stages improves the stability. Without dynamic sealing, the leakage point is the leakage of the medium in the pump well along the cable, with Zero leakage. They are adequately cooled by pumping medium, with no explosion-proof requirement, and high safety and reliability. Vibration, liquid level, temperature, and pressure monitoring systems are provided to ensure the safety of the pump operation.

- Capacity 600m3/h

- Head ~3000m

- Design Pressure ~15Mpa

- Temperature ~-196℃

- Speed 3000r/min

- Power ~2800KW